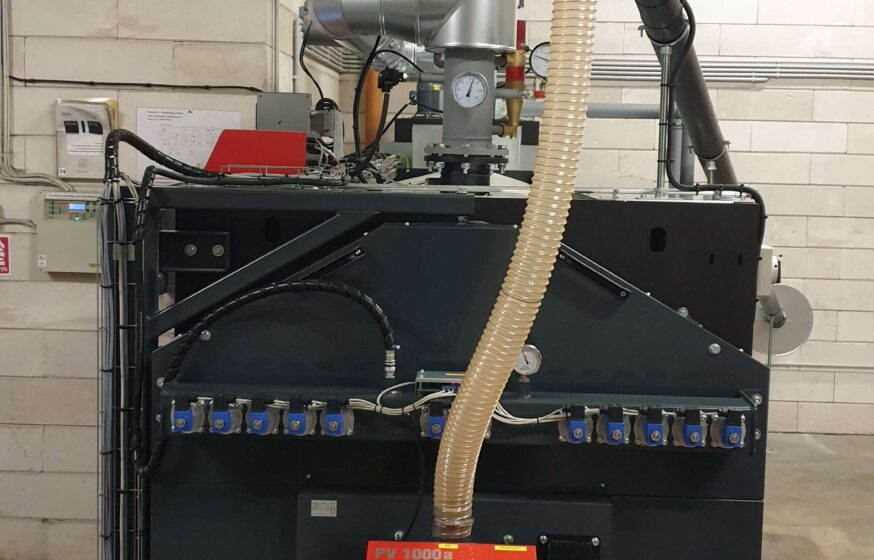

Construction and installation of a pellet heating boiler house with a capacity of 0.9MW

Description

The original task of the customer was to replace the existing wood chip stove with a more powerful pellet boiler – to design and build a fully automatic wood pellet boiler house with a fuel bunker. A biofuel boiler with a heat capacity of 0.9 MW was designed in the boiler house. The existing 0.9 MW gas boiler with the existing burner remained the reserve boiler. The type of biofuel used is wood pellets, and the reserve fuel is natural gas. The content of the work was to design an automatic biofuel boiler house that works without the constant presence of a person (unmanned).

A fully automatic pellet burner with a reserve heating boiler is intended for heat supply. The boiler house has an existing automatic reserve boiler activation system, which consists of a motorized rotary valve located on the return pipe of both boilers, a temperature sensor on the supply pipe of the pellet boiler, and a two-stage temperature regulator. In a normal situation, the pellet stove works, and the gas boiler’s rotary valve is closed. When the heating water temperature of the pellet boiler drops to the first stage, the rotary valve of the gas boiler is opened, and the boiler starts. When the temperature of the heating water of the pellet boiler drops to the second level (probable cause of the failure of the pellet boiler), the rotary valve of the pellet boiler is closed, and only the gas boiler remains in operation. When the heating water temperature of the pellet boiler rises to the corresponding level, the rotary valve of the pellet boiler is opened, and the gas boiler is stopped. The boiler house works unmanned, and all work is automatic according to the boiler house’s capacity change.

Customer | Fors MW AS |

Fuel | Wood pellet |

Power | 0.9MW |

Project | Construction and installation of a pellet heating boiler house with a capacity of 0.9MW |

Installed | 2022 |

Why are we a good partner?

At Tamult, we pride ourselves on offering our partners and customers unparalleled expertise in the bioenergy field, along with high-quality delivery, installation, and exceptional after-sales service. Our commitment to excellence is not just a promise but a proven track record:

- Testament to Durability: The oldest device we’ve set up is still operational after over 25 years, symbolizing our commitment to lasting quality.

- Designed for Longevity: Our modern boiler houses are built to last, with an estimated lifespan of over 20 years and maintenance costs only amounting to 10-20% of the initial purchase price.

- Innovation at Its Core: Our factory is a hub of innovation, constantly exploring new ways to enhance product efficiency. Rest assured, every product that leaves our facility meets all regulatory standards and customer requirements.

Choose Tamult for a partnership that guarantees not just cutting-edge solutions but also enduring value and support every step of the way.

Our sertificates

Our partners

Contact us